- Overview

- Inquiry

- Related Products

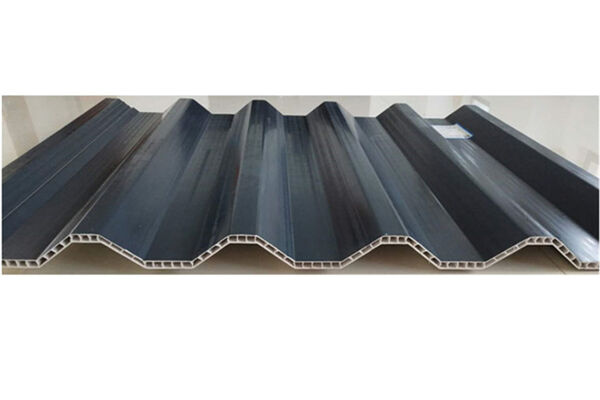

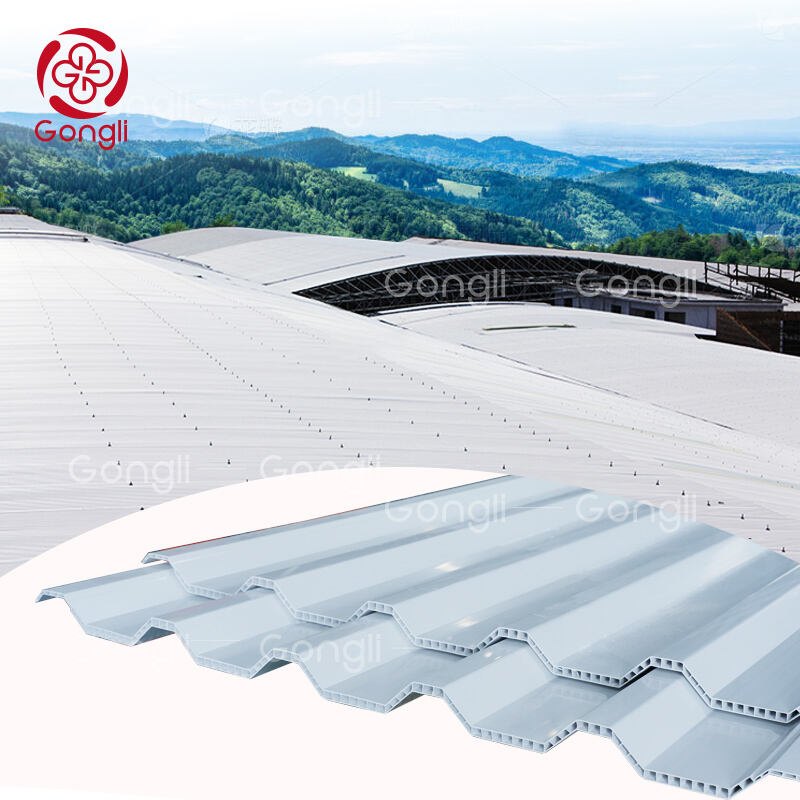

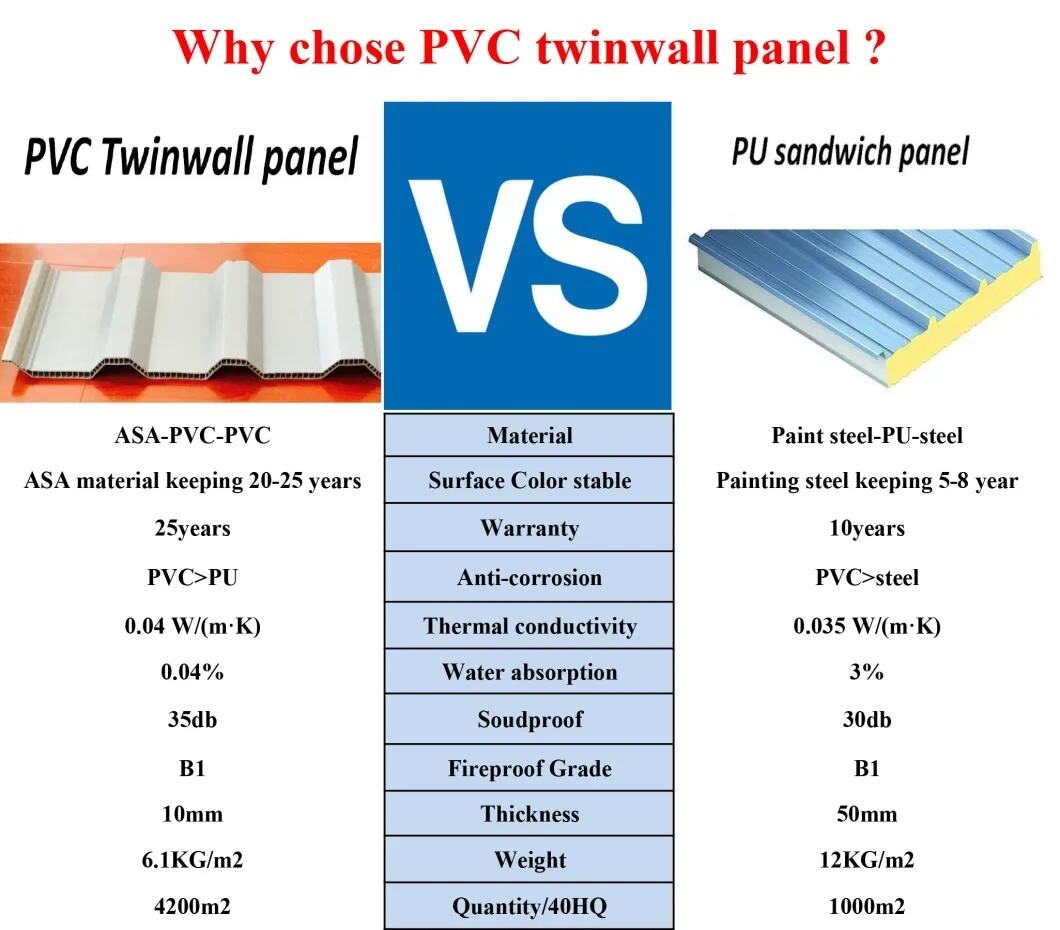

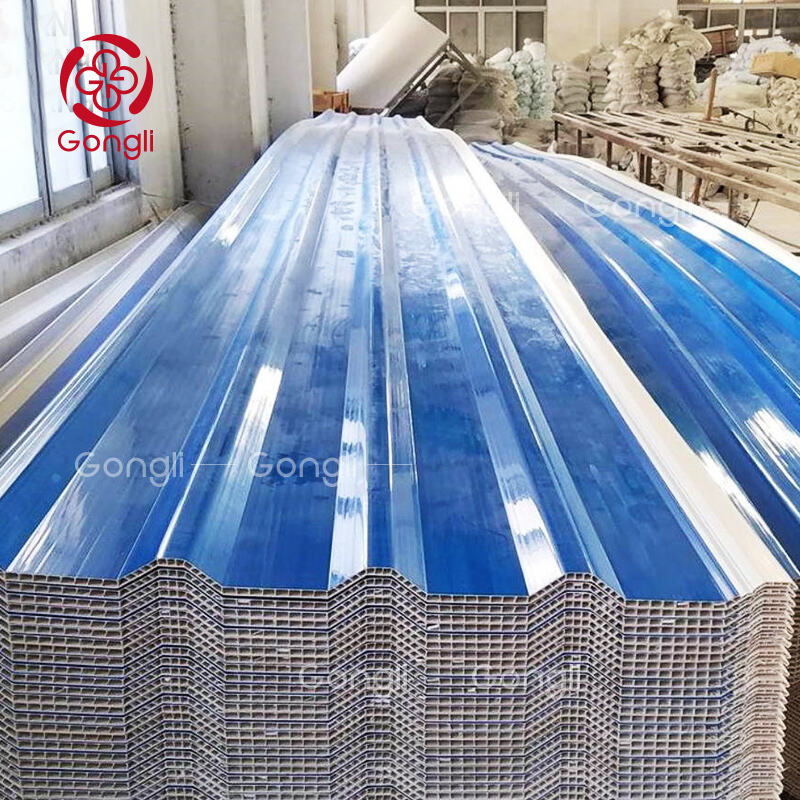

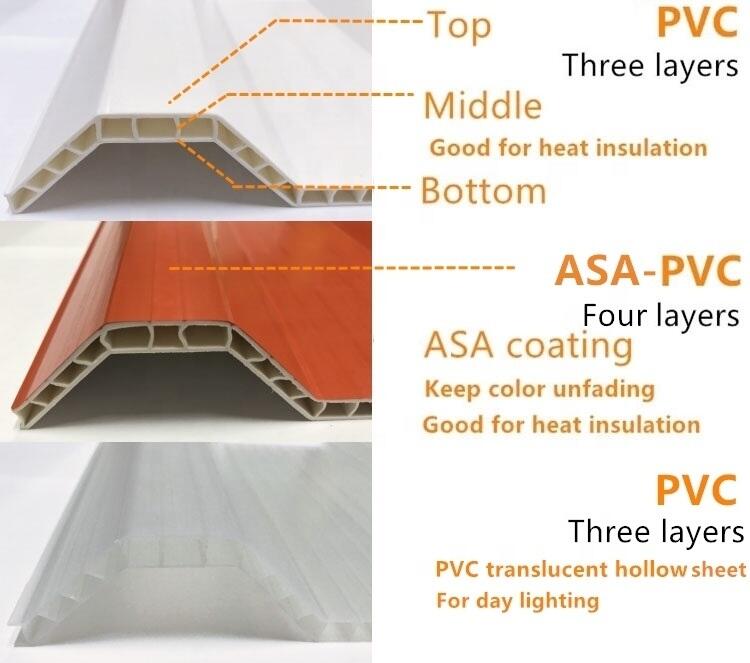

PVC Hollow Sheets are designed for both wall and ceiling applications, providing exceptional insulation and durability. They're ideal for maintaining a dry environment with easy installation.

Product name |

PVC hollow roof sheet |

Raw materials |

PVC, UPVC |

Surface materials |

ASA |

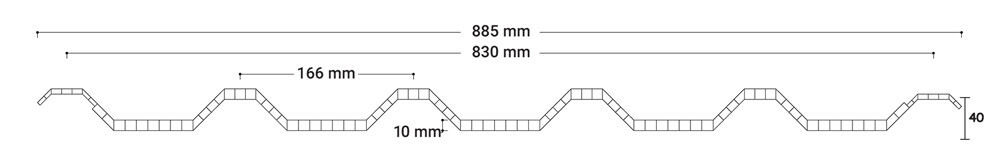

Total Width |

885mm |

Efficient Width |

830mm |

Length |

Max length in 40ft container 11.8m Max length in 20ft container 5.8m |

Thickness |

10mm |

Quantity |

4900sqm / 40HQ |

Purlin distance |

Max 1.2m |

Insulation effect |

reduce 28% temperature |

Shape |

trapezoidal wave |

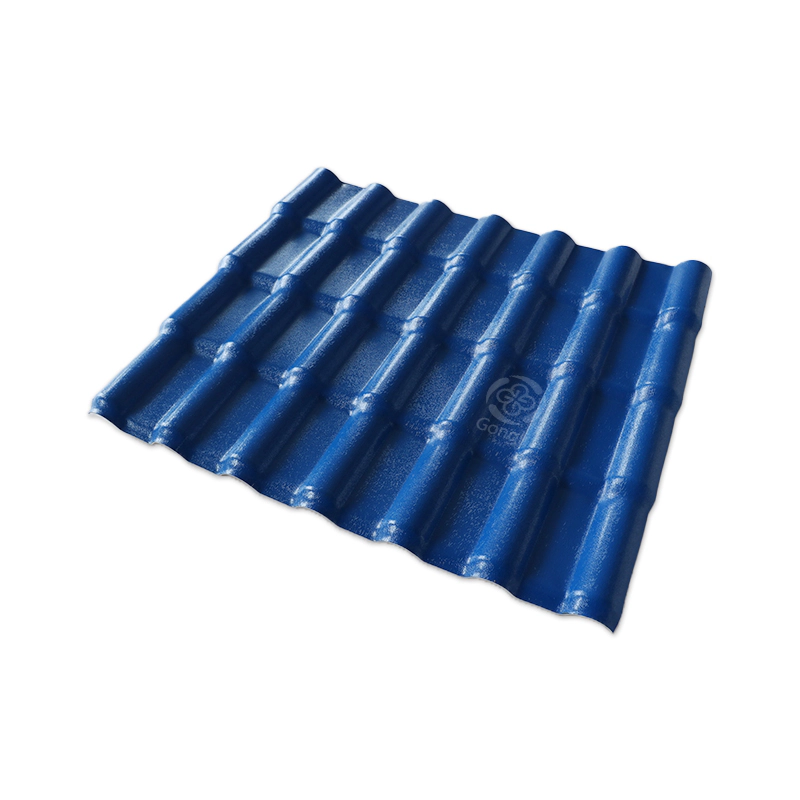

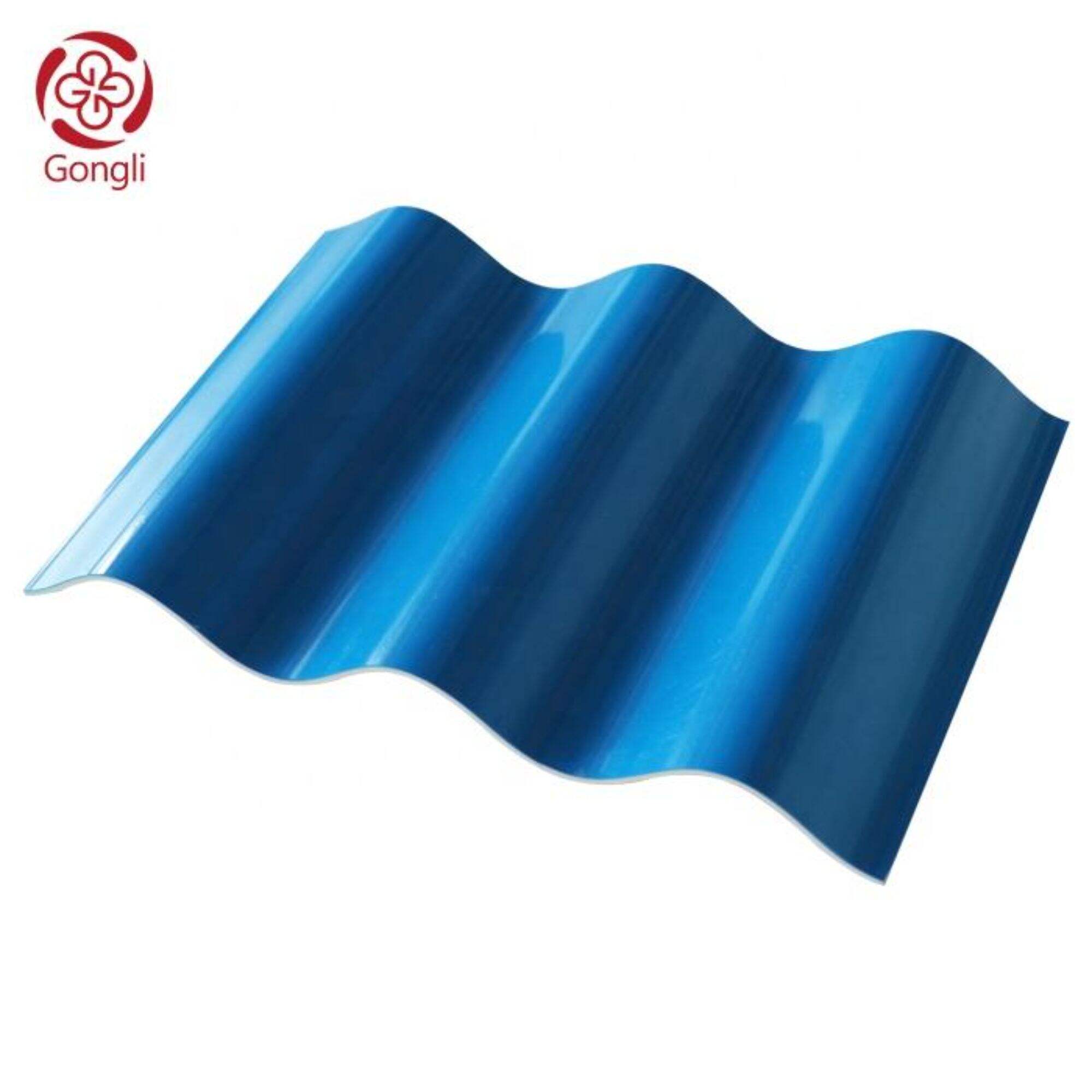

Color |

white, blue, green, gray,brick red, yellow, etc. |

Color lasting |

30 years with ASA |

| Warrant period | 10 years |

| Product life | About 20 years, even more longer without man-made distruction. |

Layers |

3-4 layers |

Features |

1.Excellent heat resistant and Anti-corrosive 2. The variety of colors and patterns |

Application |

Farm house, warehouse, chemical factory, wall cladding, and some other projects, etc. |

Test Report of pvc twinwall panel

NO. |

Test Item |

Test Method |

Test Condition |

Test Result |

|

1 |

UV Exposure |

ASTM G154-12 ASTM D2244-11 |

ASTM G154-12 cycle 1, Lamp type:UV340, Exposure period:200h |

ΔE*ab=0.5 |

|

2 |

Tensile Strength |

ASTM D638-10 |

Testing speed: 50mm/min |

26Mpa |

|

3 |

Flexural Strength |

ASTM D790-10 Procedure A |

Testing speed: 1.3mm/min Span:48mm |

52Mpa |

|

4 |

Impact Resistance |

ASTM D5420-10 |

Geometry GE(Ø12.7mm) Impact Weight:0.9kg |

Mean Failure energy:4J |

|

5 |

High Temperature Resistance |

60℃, 6h |

No visible change |

||

6 |

Low Temperature |

-35℃, 6h |

No visible change |

||

7 |

Chemical Resistance |

70% Ethanol solution(v/v), Immersion test, 23℃, 2h |

No visible change |

||

10% NaOH solution Immersion(m/m), test, 23℃, 2h |

No visible change |

||||

Saturated NaCL solution(m/m), Immersion test, 23℃, 2h |

No visible change |

||||

8 |

Thermal Conductivity |

ASTM C518-10 |

Mean Temperature 25.58℃ |

Temperature difference 9.36℃ |

Thermal Conductivity 0.071[(W/(M.K)] |

9 |

20mm Vertical burning test |

UL94-2013 Section 8 |

Specimen: 129×12.5×3.0mm |

V-0 |

|

10 |

Sound Insulation |

Compare with metal roof tile |

30dB lower |

||

11 |

Hard to Burn |

B1 Grade |

Oxygen index 32.4 |

||

Perfect for landscape projects, these lightweight panels are suitable for enhancing the aesthetic and functionality of walls and ceilings in structures that demand superior insulation and protection against water damage.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

LT

LT

VI

VI

TH

TH

TR

TR

AF

AF

MS

MS

KM

KM

LO

LO

MY

MY