The Essentials of Synthetic Resin Tile Manufacturing

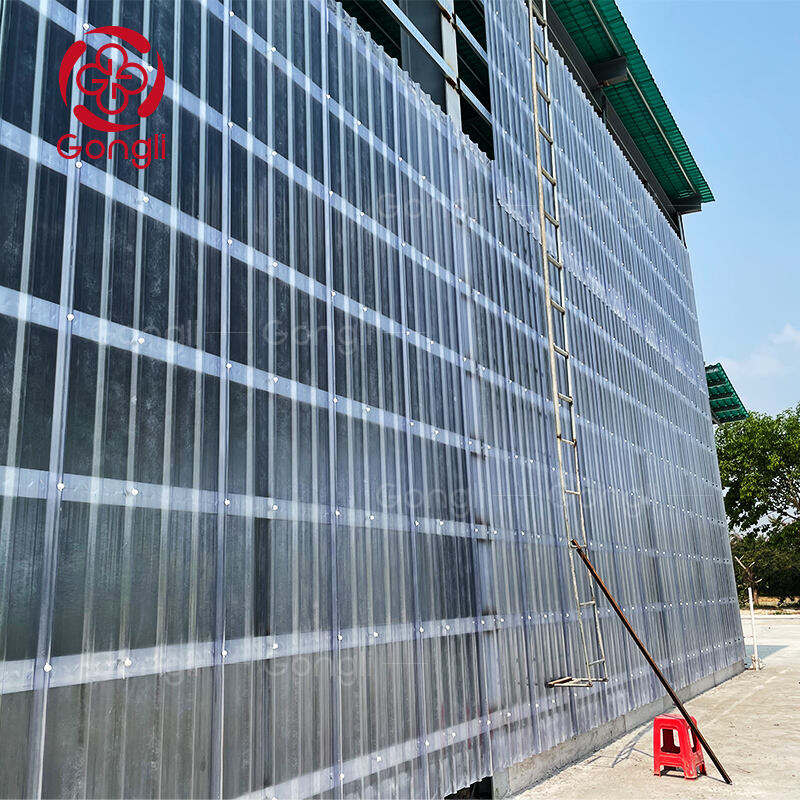

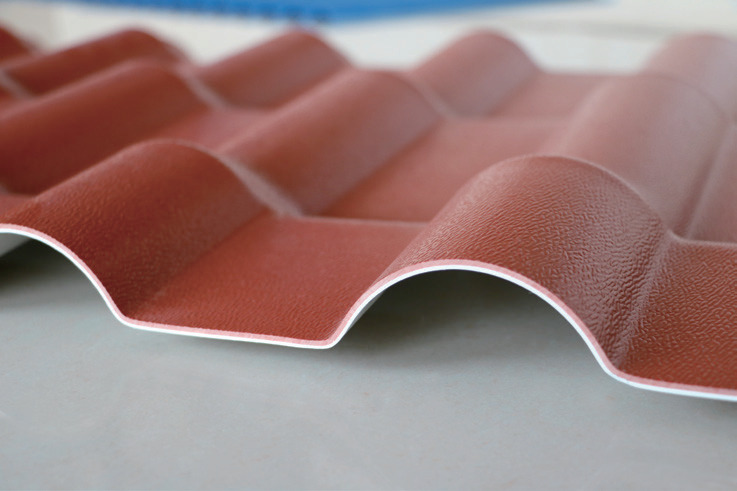

Synthetic resin tile is a common roofing material, because of its light weight, durability, beautiful features, is widely used in all kinds of buildings.

The main raw material of synthetic resin tile is polyvinyl chloride (PVC) resin, by adding various auxiliaries and fillers, through mixing, melting, extrusion and other processes, to prepare into sheet or granular resin materials.

The prepared resin material is put into the mold, and the material is melted and filled with the whole mold by pressure and heating. In this process, too high or too low temperature will affect the performance and stability of the product.

After forming, the resin tile needs to be shaped by natural cooling or forced cooling to eliminate internal stress and contraction, and ensure the size and shape of the product is stable.

Finally, it is also necessary to carry out post-processing processes such as surface treatment, cutting and packaging of synthetic resin tiles to ensure the quality and beauty of the products.

Because the production process of synthetic resin tile involves many links and factors, it is necessary to carry out strict quality testing during the production process and before the product is produced, including the detection of appearance, size, physical properties and other aspects to ensure product quality.

Recommended Products

Hot News

-

How to choose the right roof tile

2024-01-24

-

PVC Plastic Tiles: The Ideal Roofing Material

2024-01-24

-

The Essentials of Synthetic Resin Tile Manufacturing

2024-01-24

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

LT

LT

VI

VI

TH

TH

TR

TR

AF

AF

MS

MS

KM

KM

LO

LO

MY

MY